#agritech: Earth Blocks

Architect, Edward Dale-Harris reports on making Compressed Earth Blocks- a more sustainable option to bricks. Not only do they keep the room cooler, the emissions from brick making are extremely high. Compressed Earth blocks also have a quicker drying time, making them more efficient and they use readily available materials- rather than costly cement which might have to be transported from elsewhere.

Will this be a worthwhile technique to apply in the Green Shoots Agritech Centre?Ed and Sarin head out to the site in Samrong for some testing.

The first thing to do is to take some earth samples and see what kind of earth is present. Is it clay or sand rich?

Digging holes for earth samples.

We dug three holes in three points across the site. One by the pond, one in the middle, one at the furthest corner. Primarily, to see if the earth quality changes.

We are not interested in the organic top soil. We are making bricks for construction not growing crops so we dug away the first 2 feet of organic earth. Usually you can see the earth is a different colour deeper down. The organic matter is dark brown or black and after a few meters, the earth (in this case) is an orange colour.

The first thing I do is squeeze it in my hand with water to see how it feels; observe the texture and stickiness. In this case it felt sandy and slightly sticky. Then I do the sediment test, to see the different partial sizes. Clay is the smallest, then silt, sand, and finally gravel.

How to do the sediment test?

You fill a 2 litre bottle ⅓ of earth, then fill the rest with water to the ⅔ mark. Then shake for 1 minute. Then leave for 24 hours. Giving time for all the clay to settle.

Test reveals sample 1: 36% clay, Sample 2: 40% clay and sample 3-30%. Very little gravel.

More clay in earth than we thought. From our observation it appeared sandy.

Usually you need between 5- 20 % clay to make compressed earth bricks, and our sample has plenty. If you have too much clay the bricks can crack when it shrinks. A little bit of shrinkage 5-10% is usually manageable any more than this can be a problem. With clay plasters you want more sand to avoid cracks.

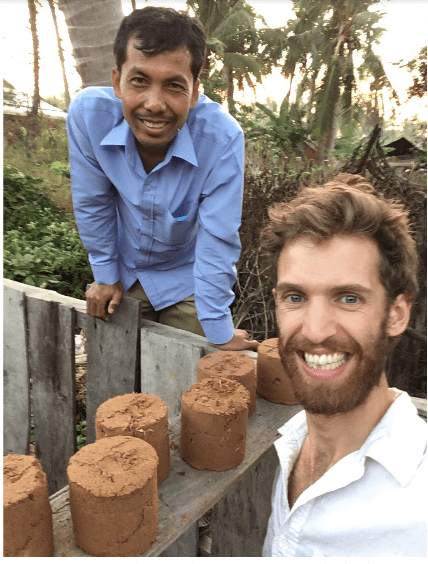

However, the best and easiest way to test the quality for earth blocks is to make an earth bock. Then see how strong it is. So we made 6 test blocks!

The photo above shows 6 test earth blocks, from three samples holes dug on site.

Sarin, the project manager at CIDO, uses this machine (below) to compact compost for mushroom growing- so the mushroom has maximum surface area to grow on. However, as it uses a similar technique as the earth block maker, we appropriated it for testing blocks.

A standard earth block maker costs around USD 2,000 and we are now testing the locally available materials to see if its a viable option.

…Stay tuned to see if the experiment worked!

–x–

If you are interested in contributing to this project, our fundraising campaign is still running- so please make a contribution and be part of the journey! https://mydonate.bt.com/events/greenshoots10nov